Purposes of a Ferrule

The ferrule is an essential component designed to create a leak-proof seal between the hose and its fittings. During hose assembly a hydraulic swaging machines is used to compress the ferrule securely clamping the end fitting to the hose, effectively preventing hydraulic oil leakage. As hydraulic oil passes through the hose under pressure, the ferrule ensures that there is no leakage or detachment between the hose and its connector, thereby supporting the safe and reliable operation of the entire system.

Proper Installation of Hose Ferrules

Accurate installation of ferrules is critical for maintaining the sealing performance and safety of hydraulic hose assemblies. The use of tight and even swaging (also called crimping) is vital, and this is best achieved with a suitably sized hydraulic swaging machines and an appropriate set of dies to suit the size and rating of the hydraulic hose being used. Selection of the appropriate ferrule and machine should be based on the specifications of the hydraulic hose in use. Prior to applying pressure during swaging, it is important to ensure correct alignment of the ferrule with both the hose and hose fitting. The swaging process can then be completed by following standard operating procedures and referring to approved ‘swage charts’ issues by the hose/fittings manufacturer.

Precautions When Using Hose Ferrules

When handling hose ferrule fittings, consider the following:

- Avoid over-tightening, as excessive force may deform or damage the hose.

- Do not apply excessive force during installation or use, to prevent damage to the ferrule or clamp ring.

- Regularly inspect connections to ensure they remain secure and maintain the integrity of the ferrule. This helps mitigate unplanned downtime or system failures.

- Use a vernier to accurately measure the diameter of the crimped ferrule and compare this to the appropriate measurement in the crimp charts.

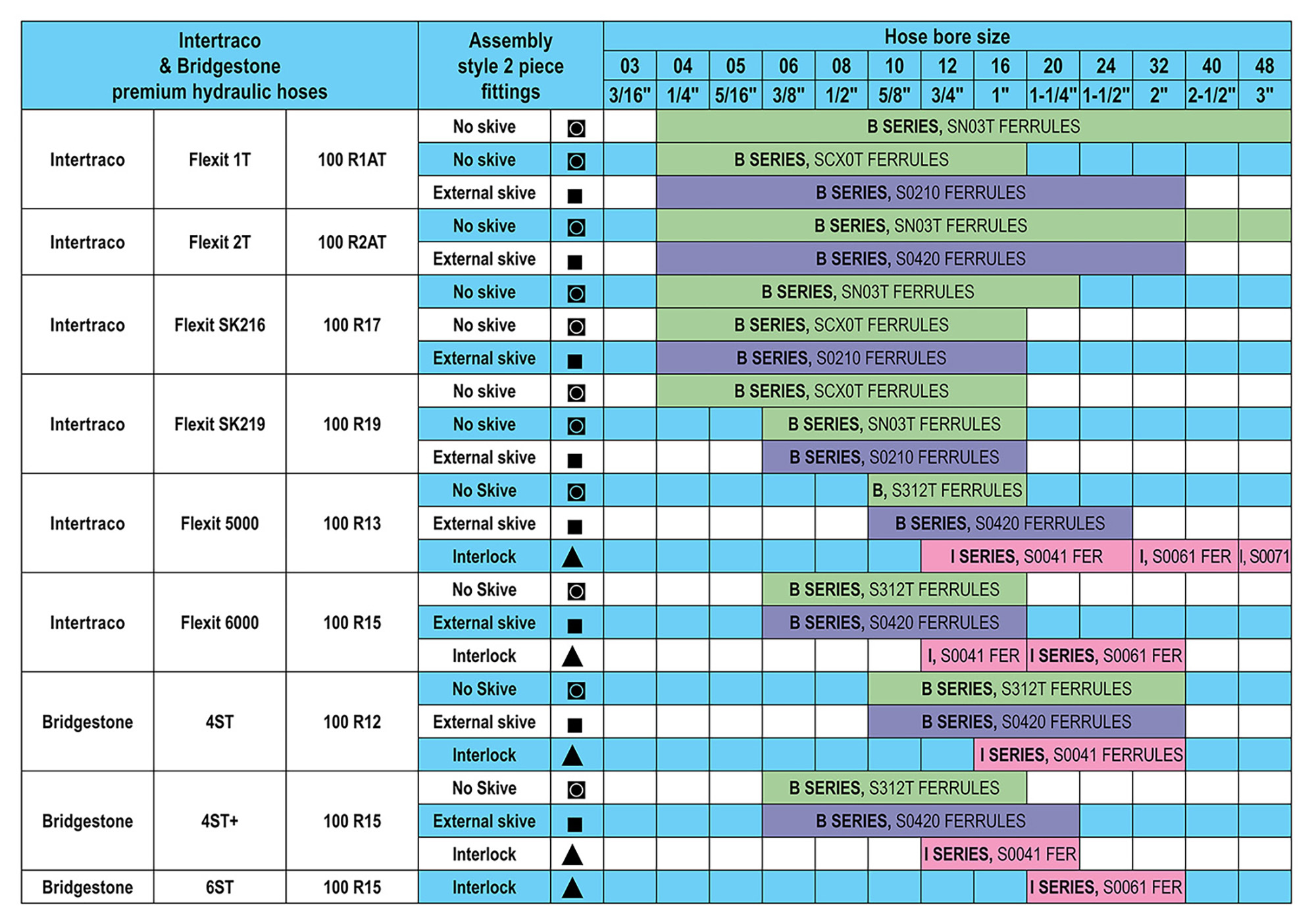

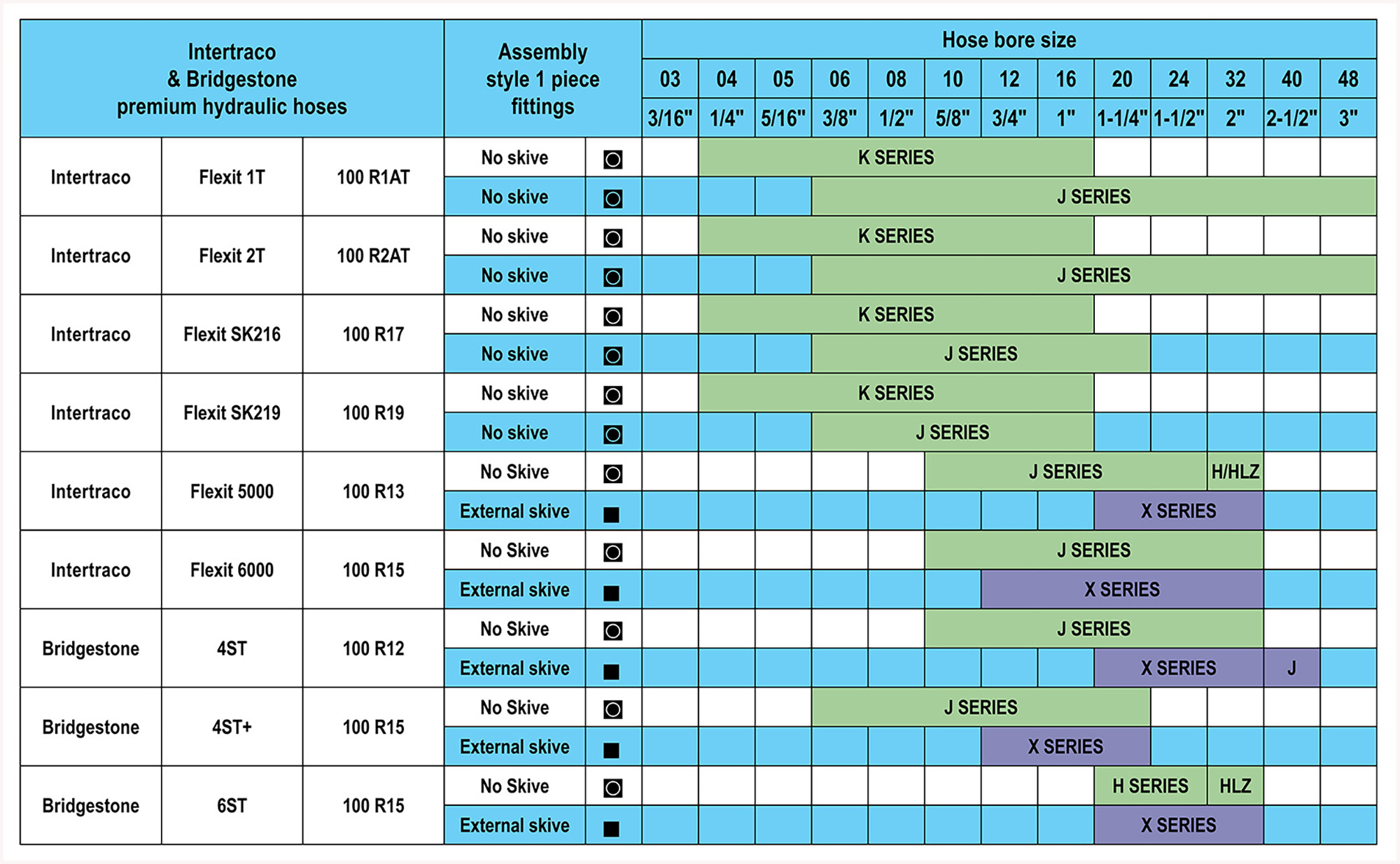

The compatibility charts for our most popular Bridgestone and Intertraco hoses are shown below.

We publish full swage charts to help our customers assure the safety and reliability of hose assemblies that they manufacture using our components. They can be downloaded by clicking here.